Grommeting

Hand Feed Grommet Press

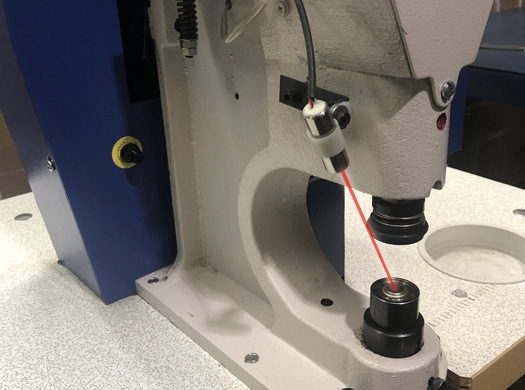

Midwest Precision Products is proud to offer the value-added capabilities of a hand grommet press for efficient production runs for small-to-mid-range projects. The addition of this economical and versatile hand feed setting machine operation allows MPP to set plain sheet metal grommets, and self-piercing grommets and washers. The press leverages a built-in laser light pointer to easily and accurately locate the center of the setting target area for a perfect grommet hole and secure setting.

MPP’s grommet setting operation features on-site tooling for key basic types of industry standard grommets including:

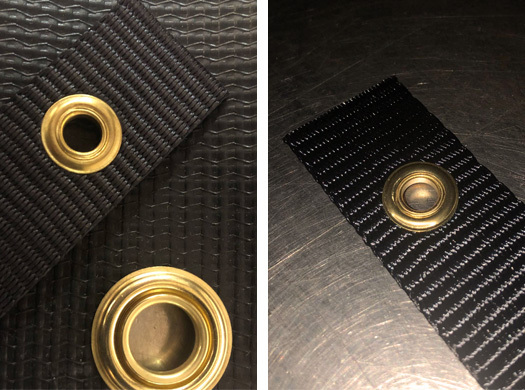

Webbing Projects

#0: Plain Sheet Metal Grommet & Flat Washers

The #0 (1/4” hole size after setting) grommet is typically used for our seatbelt webbing. Because the webbing is tough, it is a two-step process: We simply punch a hole through the webbing with one set of tooling, then secure the grommet through the punched hole with a second set of tooling.

| Part Number | #3 |

|---|---|

| Hole size after setting | 7/16 |

| Grommet Flange diameter | .970 |

| Length under flange | .185 |

| Inside diameter of washer | .546 |

| Outside diameter of washer | .970 |